Precision Engineering

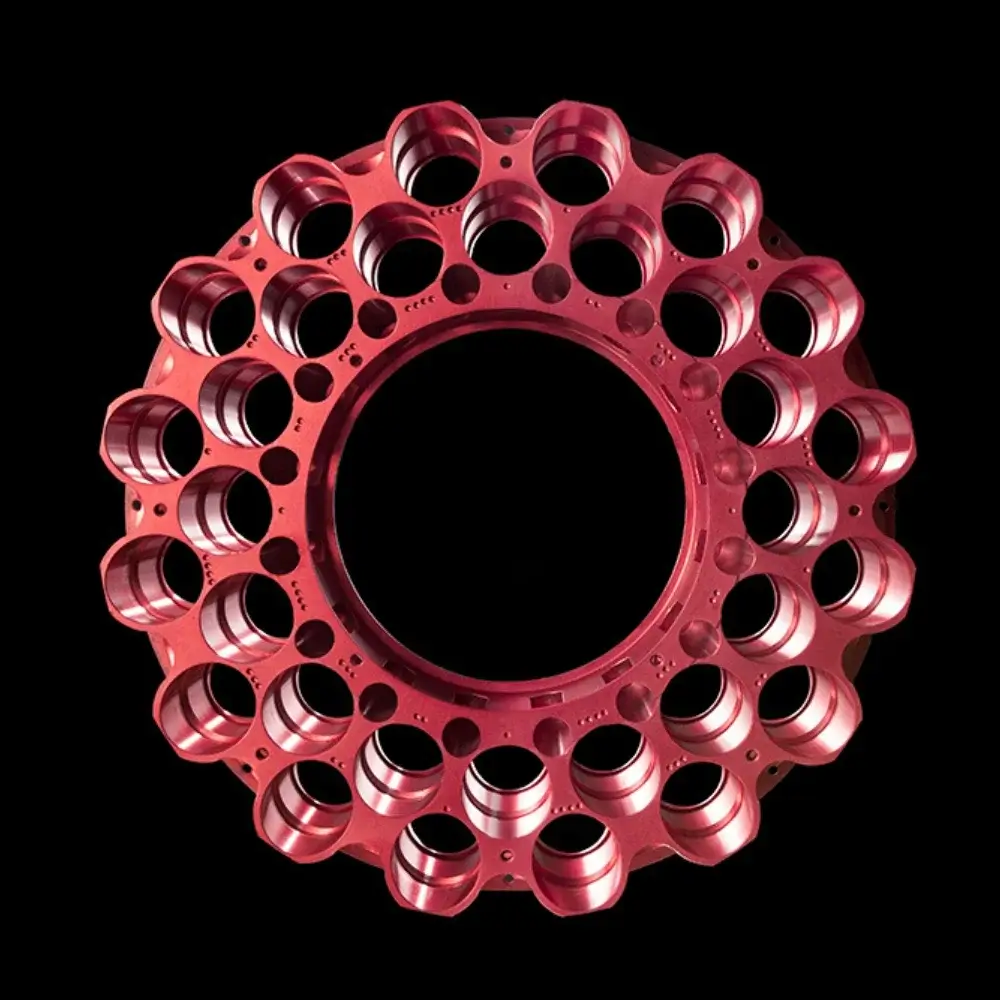

CNC Turning Services

Materials

We hold a wide range of metals and plastics for CNC machining, with applications in multiple industries. Please contact us with specific questions about your material needs.

Aluminium

Stainless Steel

Brass

Acetal/Plastics

Titanium

Copper

Inconel

Monel

Surface Finishes

Improve your part’s performance by selecting high-quality surface finishes that enhance the roughness, hardness, chemical resistance and cosmetic features of your finished component.

Your Project – Our Precision

Here’s how it works:

View our Certifications

The Numbers

CNC Turning Explained

What is CNC turning and how does it differ from CNC milling?

CNC turning is a subtractive manufacturing process that shapes a workpiece by rotating it on a lathe while a cutting tool moves in a linear motion. This process removes material around the circumference, creating cylindrical parts with precise dimensions. Unlike CNC milling, where the workpiece is stationary and the cutting tools rotate and move across it, CNC turning primarily involves the rotation of the workpiece to achieve the desired shape.

Can CNC turning produce complex shapes?

Yes, CNC turning can produce a variety of complex shapes. While it is best known for creating cylindrical and round shapes, advancements in CNC technology and live tooling capabilities allow for the inclusion of additional features such as threaded holes, slots, and flats. This makes CNC turning a highly versatile process for manufacturing complex parts.

How does CNC turning ensure part consistency in high-volume production?

CNC turning ensures part consistency in high-volume production through precise control of the machining process, automated tool changes, and rigorous quality control measures. The use of computer programming minimizes human error and allows for the exact replication of parts, ensuring that each piece meets the specified dimensions and tolerances.

Can CNC turning be combined with other manufacturing processes?

Yes, CNC turning is often combined with other manufacturing processes, such as CNC milling, to create parts with complex geometries that require features not achievable with turning alone. This hybrid approach leverages the strengths of each process to produce high-precision, multifaceted components efficiently.

CNC turning can be used in conjunction with additive manufacturing (AM) in a hybrid approach to component production. This method combines the precision and material properties of CNC machining with the design flexibility and complexity achievable with AM. For instance, a part might be additively manufactured to near-net shape, then finished with CNC turning to achieve critical dimensions and surface finishes. This hybrid approach leverages the strengths of both technologies, offering innovative solutions for complex manufacturing challenges.

Can CNC turning integrate with quality inspection systems?

Yes, CNC turning can integrate with quality inspection systems to enhance the precision and efficiency of production. Many modern CNC lathes are equipped with in-process measurement tools that can perform quality checks during machining, automatically adjusting parameters to maintain dimensional accuracy. Additionally, post-process inspection can be streamlined through integration with advanced measurement technologies, such as 3D scanning, to ensure parts meet strict tolerance requirements.

We can cater to almost any industrial applications, including:

Submit Your Project Requirements

We can provide you with a quote and lead time

- Submit Project Requirements

- Receive Quote

- Production

- Quality Control

- Receive Components