Precision Engineering

Scientific Instruments

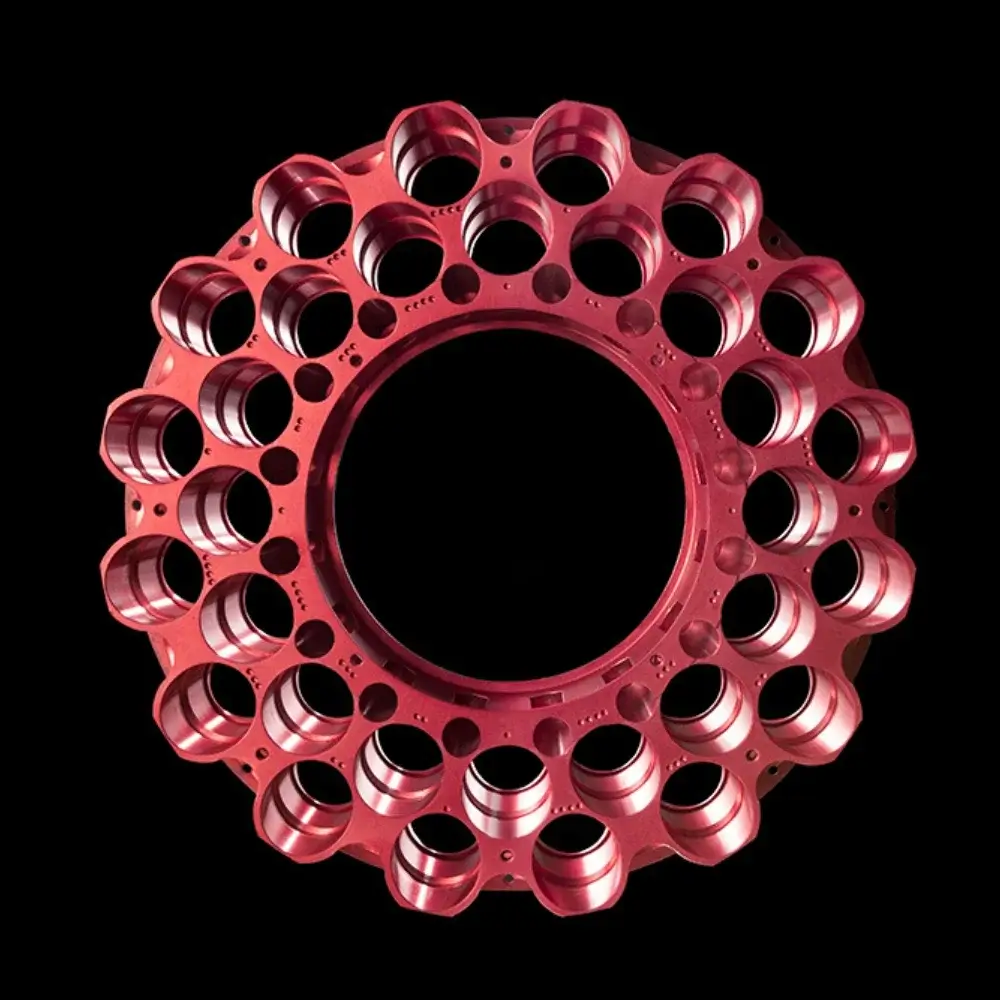

Our Scientific Instruments Applications

Our specialised CNC machining services are at the forefront of supporting innovation across a broad spectrum of scientific endeavors, from spectroscopy and imaging to the precision requirements of etch and deposition equipment, and the critical safety demands of devices utilizing radioactive sources. Partnering with us means choosing a leader in precision manufacturing, dedicated to enhancing the performance and reliability of your scientific instruments. We empower researchers and industry professionals alike with the tools they need to explore, discover, and innovate, pushing the boundaries of what’s possible in the scientific community.

Spectroscopy and Imaging

In the scientific instruments industry, spectroscopy and imaging stand as pillars of modern analysis, offering unmatched insights into the composition and behavior of materials at the molecular level. At Adaero, our precision manufacturing process allows us to create components that are essential for the accuracy, reliability, and performance of these sophisticated analytical tools.

With our advanced CNC technology and extensive experience in precision engineering, we provide solutions that meet the high standards required for cutting-edge spectroscopy and imaging applications.

Etch and Deposition Equipment

We support the evolution of these technologies through our expert CNC machining services. Our ability to produce high-precision components is crucial for the optimal performance and reliability of etch and deposition equipment. We deliver solutions that meet the exacting demands of the scientific instruments industry.

By partnering with Adaero, manufacturers of etch and deposition equipment gain access to components that enhance the precision, efficiency, and capabilities of their systems, ensuring they remain at the forefront of innovation and technology development.

Research Instruments

We specialise in CNC machining services that support the development and maintenance of high-quality research instruments. Our CNC technology and meticulous attention to detail enable us to produce components that meet the stringent specifications required for the complex mechanisms of these devices. By partnering with us, manufacturers and research institutions can enhance the performance and longevity of their instruments, ensuring precise and reliable data collection.

Radioactive Sources

These sources require the highest standards of precision and safety in their construction and handling, underscoring the need for components that ensure their secure and effective use. We can provide expert CNC machining services tailored to the production of components for devices that utilise radioactive sources. Our advanced CNC technology and rigorous attention to quality control enable us to manufacture parts that meet the exacting requirements of safety, reliability, and precision demanded by applications involving radioactive materials.

Manufacturing Capabilities

We operate to ISO 9001 & 14001 standards

Your Project – Our Precision

Here’s how it works:

Submit Your Project Requirements

We can provide you with a quote and lead time

- Submit Project Requirements

- Receive Quote

- Production

- Quality Control

- Receive Components