Precision Engineering

Forensic Equipment

Our Forensics Applications

Precision components for forensic applications are meticulously machined, deburred, and finished to meet the stringent standards required by the industry. For years, Adaero has been a trusted partner in the forensic sector, delivering high-quality components for critical applications in evidence analysis, including fingerprint detection, document examination, and trace evidence analysis, with components rigorously inspected at every stage of production to ensure adherence to specifications.

Document Analysis Equipment

This specialised equipment is crucial for analysing handwriting, detecting forgeries, and revealing any alterations or tampering with documents. Precision in manufacturing these devices is non-negotiable, as the smallest detail can be the key to solving complex cases. At Adaero, our advanced CNC machining services are at the forefront of producing high-precision components for document analysis equipment.

Our expertise in precision machining allows us to create parts with the utmost accuracy and quality, meeting the forensic industry’s stringent requirements. By choosing our CNC machining solutions, forensic experts can rely on equipment that offers unmatched reliability and detail in document examination, propelling their investigations towards conclusive results.

Forensic Light Sources

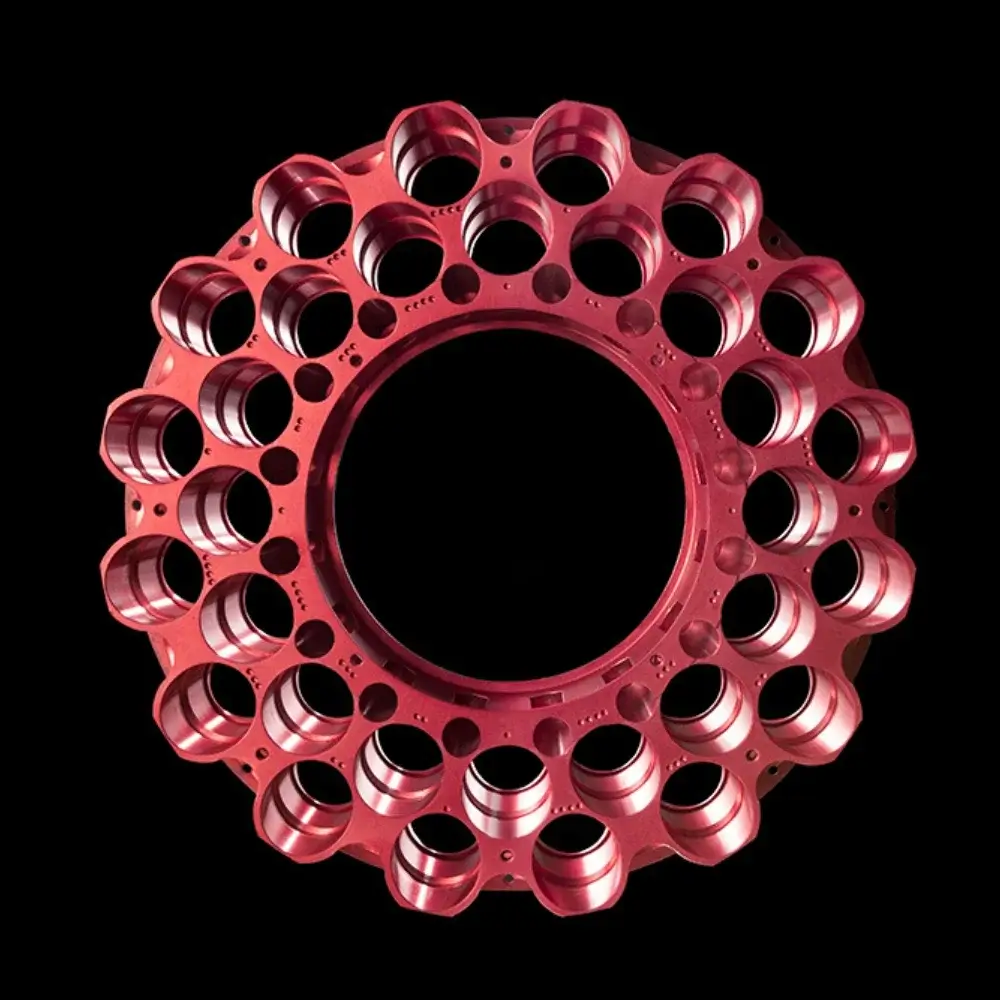

In the critical field of forensic investigations, light sources are indispensable tools that illuminate the path to uncovering hidden evidence. Forensic light sources are used to reveal substances invisible to the naked eye, such as fingerprints, bodily fluids, and trace evidence, playing a crucial role in solving crimes with precision and speed. We understand the importance of these sophisticated devices in forensic science.

Our advanced CNC machining services are expertly tailored to produce components for forensic light sources with unparalleled precision and reliability. Our commitment to quality ensures that each part meets the exacting standards required for forensic analysis, enhancing the capability of forensic professionals to conduct thorough and effective investigations.

Multi Spectra Illumination

Multi-spectra illumination technology is revolutionising forensic investigations, offering unparalleled precision in detecting and analysing evidence across various spectra. This advanced technology enables forensic professionals to discern subtle details and evidence invisible under standard lighting conditions, from biological fluids to latent fingerprints, ensuring no clue goes unnoticed.

Our precision-engineered components are integral to the development and functionality of multi-spectra illumination devices, offering unmatched accuracy and reliability. By harnessing the capabilities of our state-of-the-art CNC machining, we ensure that forensic experts are equipped with the highest quality equipment, designed to meet the rigorous demands of modern forensic science.

Trace Evidence Analysis

Trace evidence analysis is a cornerstone of forensic science, offering critical insights into the materials and substances present at a crime scene. This meticulous process involves the examination of fibres, hair, soil, glass, and other particulate matter to link a suspect or location to criminal activity. Precision and accuracy in the equipment used for trace evidence analysis are paramount, as the smallest detail can provide the breakthrough needed in complex investigations.

We specialise in providing the high-precision CNC machining services essential for manufacturing the advanced components that make up the cutting-edge equipment used in trace evidence analysis. Our commitment to excellence ensures that every piece we produce meets the exacting standards required for forensic applications, enabling forensic professionals to conduct their analyses with the highest level of confidence.

Fingerprint Detection

Fingerprint detection stands as a fundamental pillar within the forensic science community, providing irrefutable evidence that can link an individual to a scene with unparalleled precision. The intricate process of collecting and analysing fingerprints requires the most advanced and reliable equipment to ensure accuracy and efficiency.

We contribute to the enhancement of this critical forensic technique through our specialised CNC machining services. Our precision machining plays a pivotal role in the manufacture of fingerprint detection equipment, and our commitment to quality and precision ensures that forensic experts are equipped with tools that meet the rigorous standards of evidence collection and analysis.

Manufacturing Capabilities

We operate to ISO 9001 & 14001 standards

Your Project – Our Precision

Here’s how it works:

Submit Your Project Requirements

We can provide you with a quote and lead time

- Submit Project Requirements

- Receive Quote

- Production

- Quality Control

- Receive Components