Precision Engineering

Medical Equipment

Our Medical Applications

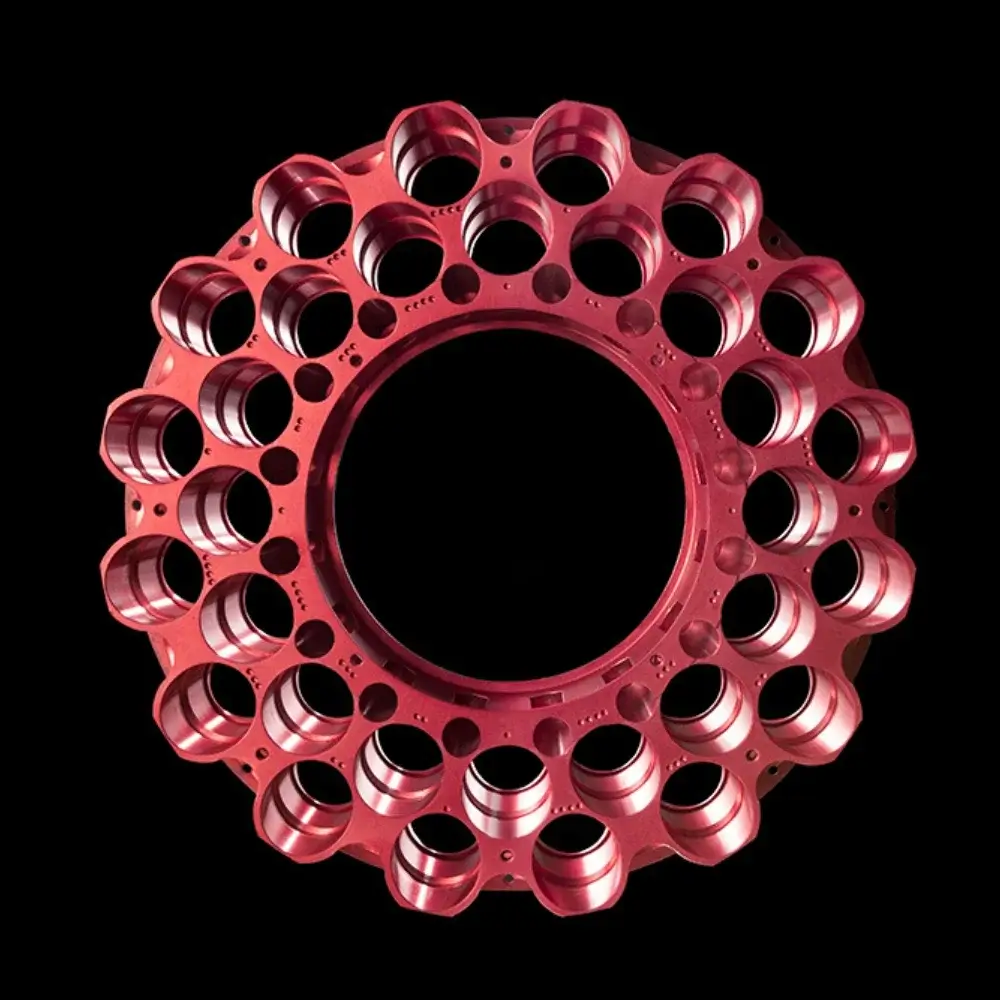

Critical components for medical applications are machined, deburred and finished to the exacting standards that the industry demands. Adaero has been working in the medical field for many years producing high quality components for anaesthesia, ventilation, resuscitation and various other healthcare products.

The machining of pneumatic or airway blocks and fittings are checked at each process stage for conformity to specification. Inspection at up to X40 magnification can be used to check bore intersections for cleanliness to ensure potentially life threatening particles such as burrs and other manufacturing waste are removed.

Ventilators

Ventilator machines must operate with flawless precision to ensure the delivery of accurate and controlled breathing support, which is why our CNC machining services are dedicated to producing high-precision components essential for the manufacturing and maintenance of ventilator systems.

Our expertise and state-of-the-art technology allow us to create parts that meet the stringent standards of the medical industry, enhancing the reliability and functionality of ventilators.

Tonometers

Tonometers are indispensable diagnostic tools in ophthalmology, providing accurate intraocular pressure measurements critical for glaucoma detection.

Our CNC machining services ensure every component meets the exacting standards required for reliable, accurate diagnostic equipment.

Otoscopes

Otoscopes enable healthcare professionals to examine the ear canal and tympanic membrane with confidence.

We manufacture precision components that ensure durability, reliability, and performance in demanding clinical environments.

Anaesthesia Machines

These sophisticated devices require the highest standards of precision and reliability. Our CNC machining services deliver components that meet and exceed rigorous medical requirements.

Our precision-engineered parts are integral to the safe and reliable operation of anaesthesia delivery systems.

Manufacturing Capabilities

We operate to ISO 9001 & 14001 standards

Your Project – Our Precision

Here’s how it works:

Submit Your Project Requirements

We can provide you with a quote and lead time

- Submit Project Requirements

- Receive Quote

- Production

- Quality Control

- Receive Components