Precision Engineering

Specialist Engineering

Our Specialist Engineering Applications

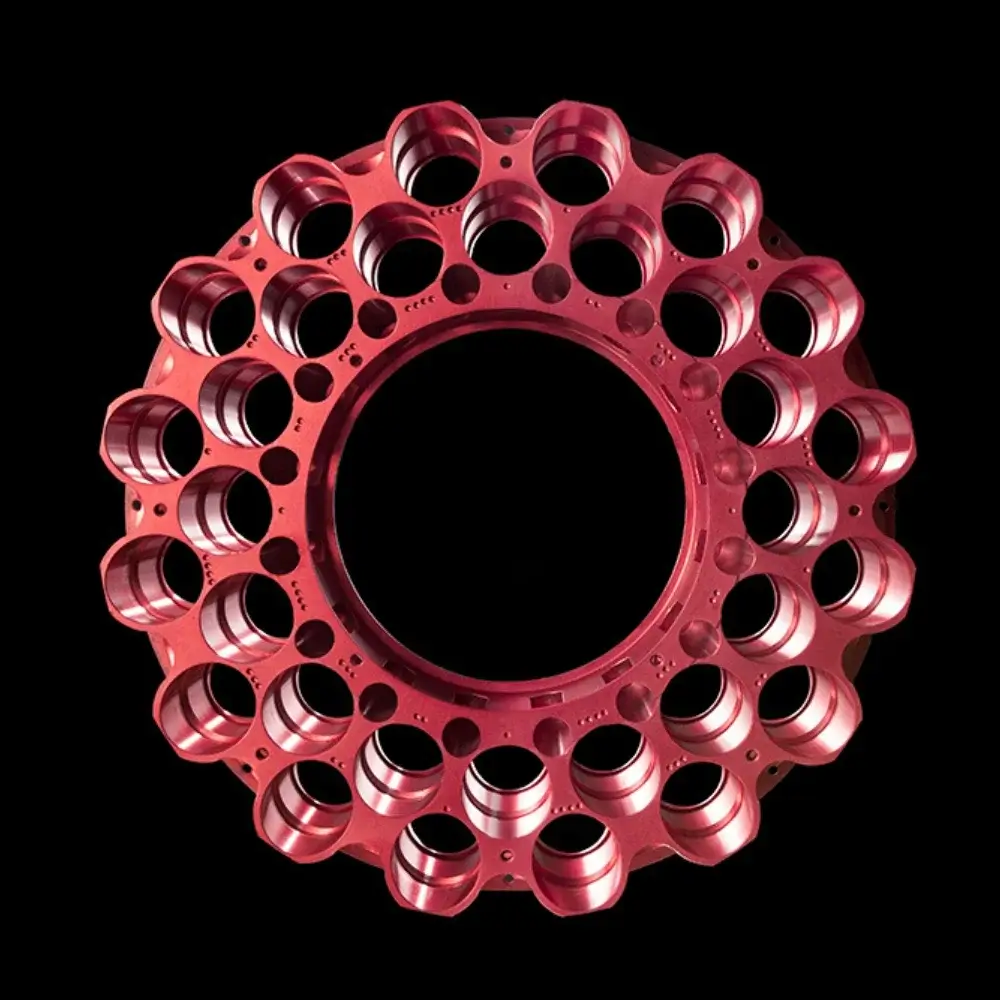

We offer manufacturing solutions across a diverse range of applications, including ground penetrating radar, pipeline mapping, and detection and measurement equipment. Our CNC technology and precision engineering capabilities enable us to produce components that are integral to the functionality and advancement of these sophisticated systems. Our commitment to quality and precision places us at the forefront of the specialist engineering sector.

Ground Penetrating Radar

Ground Penetrating Radar (GPR) technology provides critical data across sectors ranging from archaeology and construction to utility mapping and environmental studies. At Adaero, we harness advanced CNC machining services to produce high-quality components essential to the manufacture and enhancement of GPR systems.

Our precision engineering capabilities ensure parts meet the stringent specifications required for optimal GPR performance. By partnering with us, organisations in the geophysical and surveying industries gain components built for accuracy and durability.

Pipeline Mapping

We support this critical sector through bespoke CNC machining services for components used in pipeline mapping technologies. Our CNC processes allow us to manufacture parts to exact specifications required by advanced mapping instruments.

Companies specialising in pipeline mapping can rely on our components to deliver durability, accuracy, and long-term reliability in demanding environments.

Detection and Measurement Equipment

Leveraging advanced CNC machining services, we specialise in producing high-quality components essential to detection and measurement devices. Our technology and attention to detail ensure every part meets exacting performance standards.

By choosing Adaero, businesses enhance the reliability and precision of their detection and measurement equipment, maintaining leadership in their respective fields.

Manufacturing Capabilities

We operate to ISO 9001 & 14001 standards

Your Project – Our Precision

Here’s how it works:

Submit Your Project Requirements

We can provide you with a quote and lead time

- Submit Project Requirements

- Receive Quote

- Production

- Quality Control

- Receive Components